Diamond grinding wheel for dressing

Author:moao Time:2021-10-18 15:04:56

In the grinding process, the edges and corners of the grinding wheel are gradually rounded and blunt under the action of friction and extrusion, or when grinding ductile materials, grinding chips are embedded in the pores of the grinding wheel surface, so that the surface of the grinding wheel is blocked, and finally the grinding wheel loses its cutting ability. Therefore, we need to dress the grinding wheel. The common dressing methods are as follows.

Turning finishing method:

The single point diamond dressing tools installed on the tool rest usually inclines about 5°~15° in both vertical and horizontal directions, the contact point between the diamond dressing tools and grinding wheel should be 0.5~2 mm lower than the axis of grinding wheel, and the diamond dressing tools should move evenly at low speed during dressing.

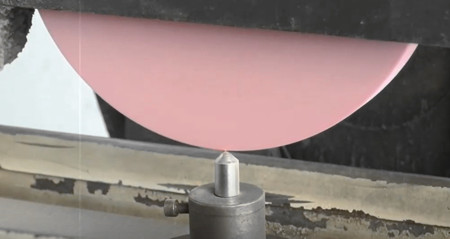

Diamond roller dressing method:

The diamond roller is made by electroplating method, which inlays a large number of diamond particles on the surface of steel roller, grinding and rolling the surface of high-speed grinding wheel at a certain speed, so that the grinding wheel can obtain a sharp working surface consistent with the profile of the roller. Diamond rollers are complex to manufacture and high in cost, but durable and efficient in dressing, suitable for dressing and grinding special shaped surfaces (such as threads, gears and turbine blades) in mass production.

Grinding wheel dressing method:

In order to achieve the purpose of dressing, adopt low-speed rotating super-hard silicon carbide grinding wheel and high-speed rotating grinding wheel to grind. or use different grain size diamond grinding wheel for grinding.

---EDITOR: Sarah Shi

---POST: Doris Hu

TAG: single point diamond dressing tool Rotary Diamond Dresser for Ceramic Wheel Dressing