The importance of binder

Author:moao Time:2021-08-25 14:04:47

Abrasive is generally composed of abrasive, bond and porosity, these three parts are often called the three elements of the consolidated abrasive. Abrasives have a cutting effect in abrasives. A bond is a material that cements loose abrasives into abrasives.

There are inorganic and organic types. Inorganic bond: ceramics, bitter and sodium silicate, etc. Organic: resins, rubber and shellac are available.

Among the most commonly used are ceramic, resin and rubber bond. In fact, in the composition of the abrasive, combined with the actual needs, there is a fourth kind of material in the abrasive, this is the filler, used to improve the performance of the abrasive, the porosity in the grinding of the abrasive chip and chip removal role, and can accommodate the coolant, contribute to the heat dissipation of grinding. In order to meet some special processing requirements, some fillers such as sulfur and paraffin can be impregnated in the pores to improve the performance of the abrasive tools.

1. The role of the bond

The function of the bond is to bond abrasive particles to form a grinding wheel. Its function is mainly reflected in the following two aspects:

(1) the abrasive can be shaped into a abrasive.

Abrasives, whether ordinary abrasives, or superhard abrasives, are barren materials, itself does not have molding properties, by adding bond, temporary bond, wetting agent to make it can be formed, and then after firing (note: not "sintering") , the abrasives are connected through the bond bridge to get the abrasives with a certain strength and hardness.

(2) Make the grinding wheel have grinding ability.

As we know, the hardness of the grinding wheel in foreign countries is also called the degree of binding, refers to the control strength of the bond to the abrasive. It can be seen that the bond performance directly affects the hardness of the grinding wheel, and the hardness of the grinding wheel is a very important performance index of abrasive tools, which directly affects the various properties of the grinding wheel in use, such as grinding ratio, self-sharpening, shape retention, etc. In the formulation of the formula, technical personnel need to select the type and proportion of the bond according to the abrasive situation, grinding parameters, workpiece quality requirements, etc., in order to make the grinding wheel with appropriate grinding capacity, to meet the processing requirements.

2. Type of bond

The commonly used bond is mainly ceramic, resin, metal three kinds, the common abrasive mainly uses ceramic, resin two kinds.

Characteristics and application range of commonly used bond

|

Common bond |

code |

characteristics |

application range |

|

Ceramic bond |

V |

strong bonding ability, good thermal stability and chemical stability, suitable for a variety of grinding fluids, and its shape retention, long life, not easy to plug, high grinding efficiency, but brittle and fragile. |

Widely used in outer circle, inner circle, plane, centerless and other grinding ways, is the most commonly used bond. |

|

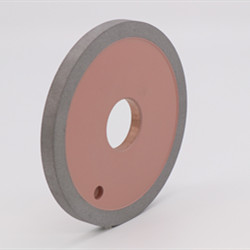

Resin bond |

B |

Has a certain elasticity and highstrength, good impact resistance. But the thermal stability is poor, the resistance to alkalinity is poor, can not be used in alkaline grinding fluid |

It is mainly used for burring in rough grinding process, grinding billet, cutting piece and some fine grinding wheels with fine particle size. |

|

Rubber bond |

R |

High strength, good elasticity, compact structure, small pores, but heat resistance, acid and alkali resistance is poor, |

Generally used for precision cutting, flexible polishing wheel and centerless grinding guide wheel . |

|

Magnesia bond |

Mg |

All aspects are poor, |

Only suitable for low speed dry grinding stone and large contact area processing. |

|

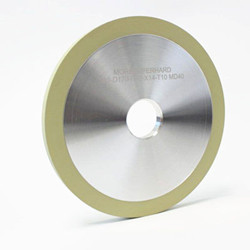

Metal bond |

M |

Divided into bronze and electroplating bond two kinds: bronze bond rigidity, high strength, good wear resistance, long service life, good shape retention, but poor self-sharpening, easy to plug, difficult dressing; Electroplating bond with high strength, sharp cutting, high grinding efficiency, no dressing, but short life. |

Mainly used for the manufacture of diamond, CBN superhard abrasive tools. |

2.1 Ceramic bond

The ceramic bond used in common abrasive tools is composed of clay, quartz, feldspar and other mineral materials, and the firing temperature is generally above 1200℃. Superhard abrasive due to the temperature sensitivity of diamond and CBN, the general firing temperature is below 900℃, and the traditional ceramic bond refractory is very high, so in fact, the "ceramic bond" used by superhard abrasive is mostly glass bond, which is mixed or melted by chemical pure compounds. Although some manufacturers use mineral materials + flux method can also reduce the refractories, but because the strength of the bond is too low, and the quality of mineral raw materials fluctuates greatly, in fact, this way is not desirable.

Table 2 is the performance comparison table of glass, ceramic and glass-ceramics bond. From table 2: glass bond with low strength, thermal expansion coefficient and the matching of CBN and diamond abrasive is poor, especially for high speed and ultra-high speed grinding wheel on grinding wheel strength demanding applications, glass bond is not suitable for, so now a lot of superhard abrasive manufacturers began to study and use of microcrystalline glass bond.

Table 2 Comparison of properties of glass-ceramics, glass and ceramic bond

|

Property |

Unit |

Glass Ceramics |

Glass |

Ceramic |

|

Thermal expansion coefficients a(20- 600 ℃) |

× 10-7/℃ |

-40~+200 |

+5~+120 |

+20~+130 |

|

bending resistance |

М Pa |

100- 400 |

50- 90 |

100- 350 |

|

impact strength |

М Pa |

0.35- 0 75 |

0. 05- 0.1 |

0 25(95%Al2O3) |

|

Unit of electrical breakdown strength |

kV/mmm |

28~50 |

25~45 |

14~25 |

The resin is "resin", and the code name for the resin bond is "B", "B" means "Bakelite", i.e., phenolic resin, so that the most commonly used resin bond is phenolic resin (about 80%). Other commonly used resins are polyimide resin, epoxy resin, polyurethane, etc.

2.2 Resin bond

Resin bond compared with ceramic bond, the holding force of the abrasive is poor, the cutting edge of the abrasive is not completely blunt has fallen off, so the resin bond is generally not used for heavy grinding (this is also one of the reasons for the resin bond grinding wheel abrasive concentration is lower and the resin grinding wheel diamond grade is lower, the surface is rough). However, it is also said that resin bonded grinding wheels are widely used in heavy grinding operations because of their high strength (less porosity) and impact load resistance. This is from two aspects: if you do not want to abrasive off the occasion, as little as possible with resin bond; Heavy grinding, cutting and other operations, especially dry grinding, due to the low processing accuracy, surface quality requirements, high efficiency of resin bond grinding wheel, natural application more. In addition, grinding fluid tends to be corrosive to the resin bond, which will reduce the strength of the bond and the control strength of the bond to the abrasive, so coated abrasive is more used in the resin bond grinding wheel.

Polyimide resins are more and more used in diamond abrasives because of their high temperature strength, corrosion resistance and wear resistance. It is said [1] : Powder resin with the same particle size must be used for diamond grinding wheels with fine particle size of W10. For example, if the tree powder has a large particle size, grinding wheels need to be pulverized when used. In fact, not only the resin bond particle size to match the abrasive particle size, ceramic bond is also the same. Guo teacher once saw a statement: "ideal situation, a grain of abrasive on average there are 4 ~ 5 particles of bond powder bonding", in fact, that is to say the two particle size is similar.

2.3 Metal bond

Metal bond is a special bond for superhard abrasive tools, including powder sintering type, electroplating, brazing, etc., among which powder sintering type is the most widely used, and its most commonly used is bronze base, cobalt base, nickel base, iron base, etc. Different systems of metal bond are used depending on the application. For example, diamond saw blades used to cut stone are usually sintered nickel-based bonds; Diamond wheels for grinding diamond tools with tungsten powder infiltrated into low melting point alloy; Wc-co diamond bit is used for geological drilling.

The metal bond grinding wheel has no pores and its bonding strength is higher than that of resin and ceramic bond, but the self-sharpening of the grinding wheel is correspondingly poor, so the sharpening of metal bond grinding wheel is a difficult problem. For this reason, metal bonded grinding wheels are more commonly used in stone, glass, semiconductor and other applications that are relatively easy to grind and do not require high grinding wheel shape retention.

Metal bond grinding wheel has high strength, good wear resistance and poor self-sharpening, which will also bring a series of problems to the use of grinding wheel. So now some scholars have studied the weakening of metal bond, which is of great significance to the production and application of metal bond grinding wheel.

2.4 Hybrid bond

Ceramics, resin, metal bond has certain characteristics, such as ceramic bond good self-sharpening, resin bond good impact resistance, high metal bond strength, but also to have certain defects accordingly, such as ceramic bond brittleness is big, resin bond abrasion resistance is poor, metal bond since the sharpness is poor, so, compound bond complement each other, to achieve the best comprehensive performance, It has become a research hotspot and is gradually applied in production. Now the most researched or applied is the composite bond mainly has the metal ceramic composite bond (metal as the main body), ceramic - metal composite bond (ceramic as the main body), resin - metal composite bond (resin as the main body). Due to the poor heat resistance of resin, metal - resin (metal body), ceramic - resin (ceramic body).

In fact, metal bond add some Al2O3, SiC, etc., resin bond add some Cu powder, Cu-Sn alloy powder, graphite, etc., these are the common practice in the industry, just the addition is called "filler", in fact, can also be called composite bond.

3. Selection of bond

The combination of resin and metal bond to abrasive is generally considered to be the mechanical inlaying force, but due to little or no pores, the grinding wheel has a high strength (although there is a saying: "Strong carbide forming elements can generate carbide and diamond reaction, the formation of chemical combination", but it's only a theory, not a strong experimental observation to the existence of the carbide), ceramic bond can form and abrasive chemical combination, but due to the brittle ceramic bond, high impact load, the abrasive loss is more serious.

The choice of bond, on the one hand, is the choice of bond type. Due to the progress of product technology, many processing areas, resin bond grinding wheel can be processed, ceramic bond grinding wheel can be processed, or metal bond grinding wheel can be processed, and how to optimize the grinding scheme, this is the industry to consider. On the other hand, is the choice of bond system. For example, there are many systems or types of each bond, and it is also very difficult to choose or prepare the bond according to the specific grinding requirements.

(2) Why can't a ceramic bond universal?

Internal grinding, external grinding and end grinding are three different grinding forms. The grinding mechanism is different, and the specific processing application is very different. Even if the ceramic bond has good performance, high strength and good toughness, it is difficult to meet the use requirements only by adjusting the grinding wheel formula.

Even if the high performance ceramic bond is used to make the grinding wheel product that meets the requirements, not to mention the previous test times, if the workpiece material and processing requirements of the customer change, the grinding wheel formula is likely to be unable to use again, and the appropriate ceramic bond can easily cope with the change of customer requirements.

Must establish their own bond system, the system of many standards, can be porosity, can also be strength, etc.

TAG: binder ceramic bond resin bond metal bond hybrid bond